In an industrial setting with machines that never stop and are always powered to their limits, even a minor mechanical problem can lead to reduced performance. Misalignment and wear are among the most common reasons why machine elements fail.

Misalignment refers to the mismatch between the shaft and mounted parts, which cannot be absolutely consistent with each other under any circumstances during use, so uneven load distribution may cause friction. Wear Occurs when rolling elements or shaft surfaces are weakened by repeated contact and stress high.

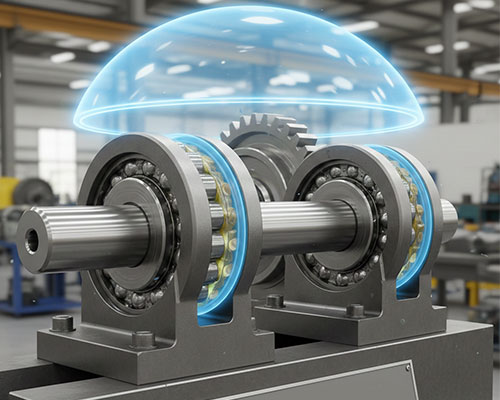

Pillow block bearings are a powerful alternative for issues like these, offering supports for all sort of rotating machinery while effectively handling stress and delivering smooth rotational function. They are critical to the longevity of machinery and costly breakdowns.

Improper alignment is not always a poor install. Even when initially aligned, shaft position can slowly change due to vibration, temperature variation and excessive operational loads. When they do, mixed members like rollers, belts and gears begin to have a sort of non-symmetric load. Whereby heat can be generated, energy wasted, and premature wear of bearings or shafts will be caused. Machines get higher power consumption, louder operation, excess vibration and eventually failures in future. Pillow block bearings are designed to offset these issues by allowing the shaft being secured to remain ever so slightly flex and give, while still keeping support.

The most important characteristic of it is the ability to allow adjustment in both the install position and the length or angle of mounting. That is practicable because of a specific construction of the bearing insert and the housing. The insert is spherically seated so as to permit the insert to self-align, with respect to the housing when the shaft is not in perfect alignment. This maintains uniform loading of the rolling elements and prevents localized overloading of the bearing. So the machine runs well with misalignment when you have structural shifting, thermal expansion, or vibration.

Wear is a major issue for any rotating system. When the stress is not uniform, then contact pressure increases, resulting in scraping of surfaces and faster wear. Pillow block bearing units are used in industrial and commercial applications including conveyors, fans and blowers, construction machinery, and processing equipment. The internal seat is a ball shaped cavity in the housing that allows free rolling of the shaft even if it does moves due to external operational action. Since the rolling elements are subjected to equal loads rather than concentration of load at a point, friction is greatly reduced. Less friction not only means the bearing runs cooler, but also it will not wear as easily or get scored on the shaft by debris.

Contaminants, such as dust, dirt and moisture or abrasive particles can often accelerate misalignment and wear. Pillow block bearings also contain bearing seals that keep contaminants away from the rolling elements. Seals retain lubricant and prevent contaminants from getting in contact with the bearing rollers, providing lubricating the bearing. This minimizes metal-to-metal contact and greatly extends the life of your bearings as well as the attached equipment. In dust-and-water-exposed applications, where parts must also be kept clean to reduce maintenance exposure (like mining, food processing, construction and agriculture).

Vibrations Industrial machines are sending continuous vibrations to equipment from the nature of their crushing, conveying and process handling work. Too much vibration puts the shafts at greater risk for misalignment and accelerates wear. Pillow block bearings, because of their pillow-like structure and the ability to be integral with a housing, have cushioning properties instilled in their material and internal geometry. This makes it possible for them to take in much of the shock and vibrations prior to transmitting them into the shaft or other machinery components. The bearings help prevent stress on parts and keep equipment in place over time. This lack of shock loading on gears, belts, sprockets and couplings means years of uninterrupted service.

Lubrication is critical in both reduction of wear and in controlling accumulation of friction. Pillow block bearings can be lubricated to very low levels due to its internal construction and sealing. Such retention minimizes the chance of a lack of water flow, hot water generation and surface scoring. The bearing provides lubricant flow around rolling elements, even on machines that have to work in deadly conditions. Consequently the wear development is dramatically slowed down and the entire system needs less maintenance.

The longer a machine stays in alignment and operates free of friction, the more dependable it is. Life: Pillow block bearings help extend the life of where use is limited due to surface damage that causes wear and tear, while ensuring a contact stress level for optimal transmission of torque. With properly working bearings, operators may expect less unplanned downtime; less spare part consumption and increased productivity. And is not only a continuity of operations solution, but reduces long term maintenance costs.

Misalignment and imbalance are the two most common enemies of rotating plant. When uncorrected, they result in excessive friction, overheating, vibration and noise – and sometimes even ruin costly investments. Pillow block bearing solve these problems to some extent at the source of trouble by providing support line at the same time as field axis, which, in addition to reducing mechanical wear and tear on motor and machinery. It also helps maintaining overall equipment life and ultimately reducing maintenance costs. For any industry that uses a lot of machinery, including manufacturing, mining, processing, agriculture or power generation; investing in reliable pillow block bearings isn't just technical decision it makes smart business sense.